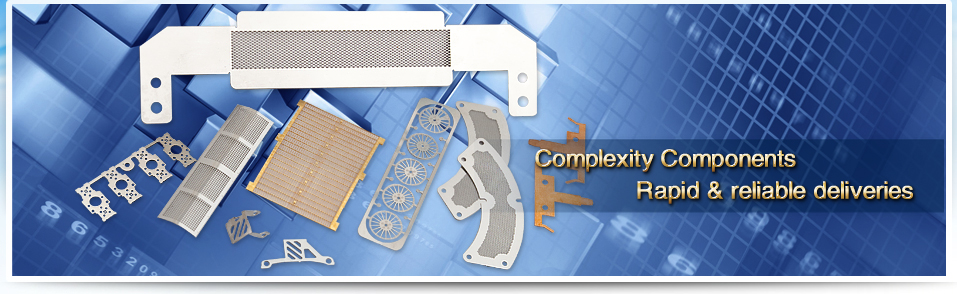

Metal etching (also known as Photo Etching and Photo Chemical Etching as well as Chemical Milling or Chemical Machining or PCM) is a technique for manufacturing high-precision flat metal parts. Metal Etching has applications in nearly every type of industry. LongFai has specialized in precision chemical metal etching for more than 15 years, working with a wide range of metals.

Typical Industry Sectors supplied by LongFai as following:

Photo Etching Photo Chemical Etching Chemical Milling Chemical Machining Metal Etching

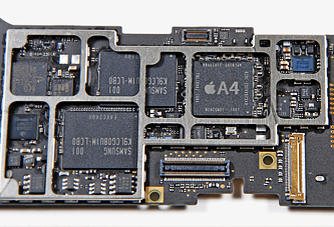

Electronics & Communications

- Interference shielding systems

- -EMI / RFI shielding enclosures

- -EMI / RFI contact strips, fingers, & gaskets

- -EMI / RFI shielding universal prototyping kit

- On PCB mechanical features, contacts, ground clips, supports, springs etc clips supports,springs etc

- Antennae and micro antennae

- Heat sinks

- Solder masks

- Lead frames

- Stencils

- Solder performs

Medical Dental

- Diagnostic equipment components for blood analysis

- Specialist scalpel blades

- Eye surgery blades

- Measurement gauges

- Orthopaedic blades

- Blood and fluid filter meshes

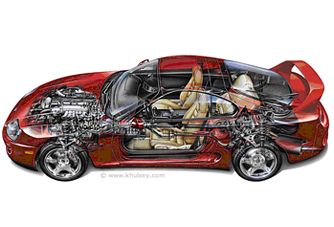

Automotive

- Shims and spacer washers

- High performance gaskets

- Meshes and filters

- Stencils for air bag manufacture

- Airbag components

- Cylinder head gaskets

- Tread plates

- Decorative trim parts

- Fuel cell plates

- Injector and fuel management components

- Clutch components

Perforated Etching

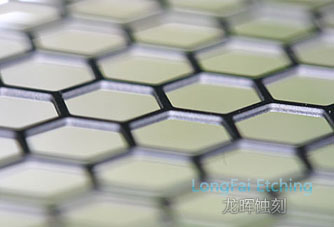

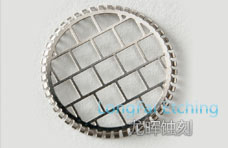

- Protective grids

- Sieves

- Food filters

- Deposition Masks

- Stands and dispensers

- Custom ornaments, commemoratives, jewelry and fine giftware

- Advertising and Branding

- Pendants

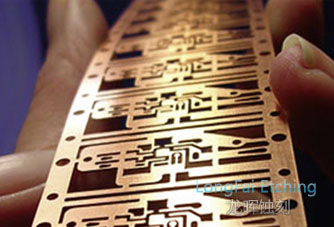

Reel to reel etching (Not available now. Welcome discuss with us to set up it. )

- The etching of reels combines the advantages of etching technology and the economy of reel-to-reel production.

- Reel-to-reel have the following advantages

- -Cost reduction with medium and larger size quantities on the one hand and with direct downline processing to clearly improve economy on the other hand.

- -Selective electroplating can make together.

- -Meet the high requirements on the absence of burrs, as well as cleanliness, and on parts that are produced with very little mechanical tension, unlike created by stamping and heat treatment.

- -Produce large series at the same time.

- -Realize specification with etched reels integrating easily into the customer’s specific processes. The reels are equipped with locating holes for controlling the cycle time of production machinery.

- The new laser marking technology enables us to print serial numbers, logos, bar codes and labels on in-house and customer parts at a later production stage.

- Ideal for stainless steel, aluminium, copper alloys

- Excellent, burr-free cutting, combined etch/laser parts

- Parallax-free positioning via special camera systems

- Up to 5 mm in material thickness